Power Electronics is a pivotal technology for enabling clean and agile electric power. Advancements in power electronic systems and components are paving the way for increasingly capable, reliable, efficient, and power-dense power management solutions. Wide bandgap semiconductor devices like SiC and GaN expand the application boundaries of power electronics systems, leading to cost reductions through reduced conversion losses, component count, and increased power density. However, the unpredictable behavior of these devices under various use cases and operational conditions poses reliability concerns, often necessitating oversizing or derating of power electronics systems. The limited availability of historical operational field data further complicates maintenance planning and warranty expenses.

Introducing the SensAI platform, PowerSensAI revolutionizes power and health management in both stationary and mobile electric-powered systems. The SensAI platform incorporates cutting-edge sensing technologies that enable accurate measurements of various parameters, allowing for the estimation of critical characteristics of different system components previously not possible. For example, it can accurately determine the resistance of power devices under dynamic and steady-state conditions. Coupled with software, the SensAI sensing platform facilitates precise modeling of power systems throughout their lifecycle.

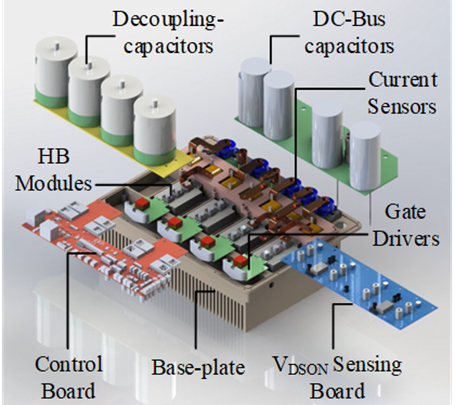

The critical feature of SensAI is its real-time modeling capability, known as a digital twin, which enables health monitoring and predictive maintenance scheduling. The platform leverages high accuracy and resolution of data processing for power management in complex and critical stationary and mobile electric-powered systems. The SensAI hardware plays a crucial role in capturing the necessary parameters to monitor performance degradation precursors in power converters. The associated firmware, preferably embedded in edge computing platforms, continuously monitors device performance. Figure 1 illustrates a generic power converter assembly, highlighting the components under the highest stress with the lowest mean-time-between-failure, along with the proposed integration of minimally invasive voltage and current sensing. The embedded edge computing platform processes real-time sensor data and generates precursor outputs indicating the state of health of the components.

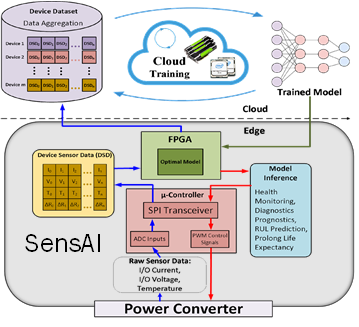

To predict the state of health and performance envelopes of devices in power electronics converters, the firmware-processed data should be input into a software package. To ensure real-time scalability, various AI frameworks can be employed, integrating a server-edge platform. The AI platform is responsible for aggregating device reliability by training AI networks. Edge inference provides real-time feedback on reliability modeling, active control, decision-making, and service quality, with minimal losses. Figure 2 depicts a functional block diagram illustrating this approach, offering a cost-effective and secure means of integrating adaptable sensors and sensor fusion.

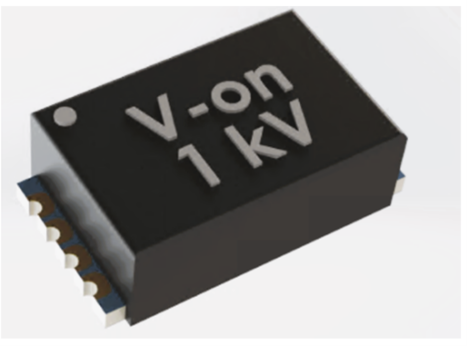

VON1k5m sensor is a critical element of the SensAI family. VON1k5m is a state-of-the-art device designed specifically for measuring the drain-to-source voltage of high-voltage power transistors with exceptional resolution during the ON-state. This sensor, suitable for in-situ instrumentation, enables the monitoring and prediction of power electronics devices’ performance at the level of power semiconductor devices. By capturing on-state voltage and current information, it enables the estimation and monitoring of the resistance of high-voltage power semiconductor devices. With its settling time of 50-200 nanoseconds and 1,000V blocking voltage capability, the VON sensor is ideal for high-frequency, high-voltage power electronics systems utilizing wide bandgap devices like SiC and GaN transistors. Its short settling time allows for the estimation of dynamic on-resistance, particularly important for GaN power devices, within 300 nanoseconds after switching transients. The VON1k5m sensor effectively addresses the need for quick and accurate voltage sensing in power electronics.

In conclusion, PowerSensAI (PSAI) is driving a revolution in the power and energy systems industry through its advanced sensing technology. By optimizing energy consumption, reducing waste, and promoting sustainable industry practices, our solutions are making significant contributions to sustainability efforts. The seamless integration and compatibility of PSAI sensors with a wide range of electric-powered systems are leading the industry towards a more efficient and sustainable future.

References:

[1] Intelligent Power Stages (IPSs), US DOE Office of Electricity TRAC Peer Review.